There are no products listed under this category.

Reliable power and strong towing performance for the 2003–2007 Dodge/Ram 5.9L Cummins (common-rail). Diesel Power Source turbos, exhaust manifolds, and install hardware improve spool, airflow, and grade control while protecting everyday drivability.

There are no products listed under this category.

This page highlights third-gen 5.9L fit notes and upgrade paths. If you need 12-valve, 24-valve (’98.5–’02), or 6.7L parts, use the links below. Detailed specs, year breaks, and exact kit contents are listed on each product page.

The common-rail 5.9L blends strong internals with responsive fueling, so airflow upgrades translate into real-world gains. A high-flow manifold and correctly matched S300/S400 single—or a compound-over-stock path—let you tow steadier, run cooler, and add power without giving up drivability.

Efficiency comes from operating the turbo in its sweet spot. A smoother manifold and properly sized turbo lower drive pressure and help combustion under load. Pair with a healthy intercooler system and proper maintenance to see steadier mileage on highway and tow routes.

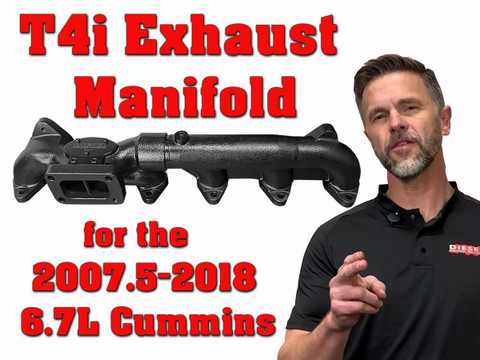

Shopping related categories? 5.9 Cummins Manifolds (12V, 24V, CR) | S300 Single Turbos | S400 Single Turbos | Add-A-Turbo (Compound-Over-Stock) Kits. For other engines, see 2nd Gen 24V (1998.5–2002) or 6.7 Cummins Manifolds (2007.5–2024).

A manifold alone typically doesn’t require tuning. If turbo size or fueling changes, calibration can optimize response and shift strategy.

Yes. Lower drive pressure and smoother flow usually reduce EGT on long pulls and help the turbo stay in an efficient range.

Choose T3 for most stock-frame or quick-spool goals. Move to T4/T4i when stepping up airflow for future headroom or larger single/compound setups.

Not required, but compounds provide the widest efficiency window for heavy GCW, elevation, or heat—keeping response strong and EGT controlled.