Manifolds

Diesel Exhaust Manifolds | 5.9L & 6.7L Cummins, 4BT/3.9L, ISX15/X15

Precision-cast, crack-resistant diesel manifolds engineered for airflow, heat control, and long service life. Options for light-duty Cummins pickups and heavy-duty ISX/X15 platforms.

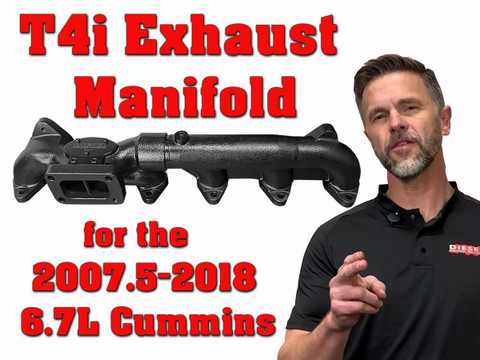

Diesel Power Source manifolds are built to move heat and exhaust efficiently so your turbo can stay in its sweet spot. Thick-wall castings, reinforced partitions, and precision-machined flanges help reduce warping and leaks. Choose direct-fit stock-replacement or performance configurations (including T3, T4, and T4i) tailored to your engine and turbo setup.

Shop by platform

- 6.7L Cummins Manifolds – Stock-replacement and T4 options for 2007.5–2024 Ram.

- 5.9L Cummins Manifolds – 12V, 24V, and common-rail applications.

- ISX15/X15 Manifolds – Heavy-duty solutions for Class 8 routes.

- Cummins 4BT/3.9L Manifolds – Compact performance for swaps and industrial.

Why upgrade your diesel exhaust manifold

- Lower drive pressure & EGT: Smoother runners and efficient collectors reduce backpressure under load.

- Faster turbo response: Stable pulse energy helps the turbo light sooner and pull harder through midrange.

- Strength & durability: Thick-wall castings, robust partitions, and flat-machined flanges resist cracking and leaks.

- Service friendly: Pre-tapped ports (where noted) simplify EGT/pressure monitoring and diagnostics.

Construction that matters

- Precision casting & machining: Flat sealing surfaces for reliable gasket crush and bolt torque retention.

- Thermal management: Designs that tolerate continuous load, heat cycling, and towing duty.

- Correct flange geometry: T3/T4/T4i styles for common turbo inlets.

How to choose the right manifold

- Keep your stock turbo? Pick a direct-fit stock-replacement manifold for OEM flange and angle.

- Upgrading the turbo? A T4/T4i performance manifold provides headroom and stable boost control.

- Tow or run hot climates? Prioritize thicker castings and proven crack resistance with monitoring ports.

When to replace your manifold

- Ticking or hissing on cold start that fades warm (leak at gasket or crack).

- Visible cracks/soot marks near divider walls or flange edges.

- Higher EGT/lag after load with no other system changes.

- Warped flanges or recurring gasket failures.

Install & maintenance tips

- Use new gaskets and quality hardware; follow factory torque sequence in stages.

- Apply high-temp anti-seize to studs/nuts; re-torque after initial heat cycles if specified.

- Inspect turbo mounting face and downpipe alignment to prevent stress on joints.

- Pressure test charge-air system and check for upstream exhaust leaks after install.

Planning supporting upgrades? See 3rd Gen Swap Kits, Add-A-Turbo Kits, and Turbonator® VGT Upgrades.

Frequently asked questions

Will a performance manifold help if my truck is emissions-equipped

Yes. Lower backpressure and steadier turbo operation can help manage heat and drivability with factory systems in place when installed as directed.

Do I need tuning for a manifold swap

Usually no for a manifold alone. If you change the turbo or fueling, a calibration update may improve response and shift strategy.

T3 vs. T4 vs. T4i—what’s the difference

T3 matches many OEM-style turbos. T4 and T4i offer more flow and are common for performance turbos. Choose the flange that matches your turbo inlet and goals.

Can I reuse studs and gaskets

New gaskets are recommended. Replace stretched or corroded studs/nuts. Always follow the correct torque pattern.

Refine: