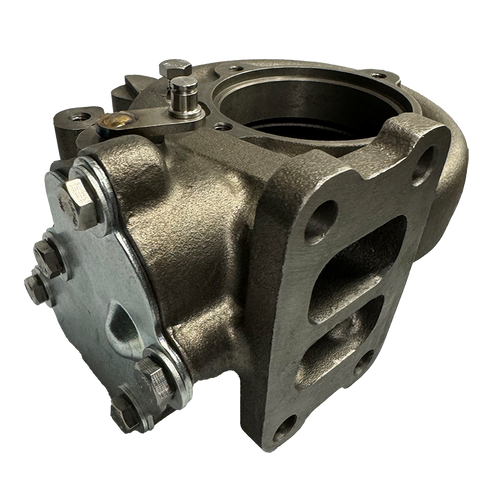

Turbine Housings

Turbine Housings for S300 and S400 Turbos

Diesel Power Source turbine housings are machined for perfect fitment and optimized exhaust flow. Each housing is engineered for efficiency, durability, and compatibility with various turbo configurations. A reliable replacement or performance upgrade for any build.

Turbo Turbine Housing FAQs

The turbine housing directs exhaust gas into the turbine wheel and controls how energy is applied to spin the turbo. Its size, A/R ratio, and scroll design directly affect spool-up, boost response, exhaust drive pressure, and overall turbo efficiency. Choosing the correct turbine housing is critical for balancing low-RPM response with top-end airflow.

A smaller A/R turbine housing provides faster spool and stronger low-RPM response, making it ideal for towing and street use. A larger A/R housing flows more exhaust and supports higher horsepower at the expense of slower spool. The right choice depends on engine size, fueling, turbo frame, intended use, and whether the truck is used for towing, daily driving, or high-power applications.

Single-scroll turbine housings combine exhaust flow into one passage, offering simpler fitment and broad compatibility. Divided or twin-scroll housings separate exhaust pulses, improving turbo response and reducing drive pressure when paired with a properly matched exhaust manifold. Divided housings are often used in higher-performance and compound turbo setups.

Yes. Upgrading to a properly sized turbine housing can reduce exhaust drive pressure, lower exhaust gas temperatures, and improve boost control under load. For towing and heavy-use diesel trucks, the correct turbine housing helps the turbo operate more efficiently during long pulls and sustained boost conditions.