ISX15 Manifold

ISX15 Exhaust Manifolds | Cummins ISX & X15 Heavy-Duty

The Diesel Power Source ISX15 manifold is engineered for demanding commercial duty. Thick-wall, high-nickel cast construction and precision-machined flanges provide thermal stability, reliable sealing, and efficient exhaust flow to help control EGT and support turbo life on Cummins ISX and X15 platforms.

Designed for tractors and vocational trucks that see long grades, high ambient temps, and continuous load, DPS ISX manifolds prioritize durability and serviceability. Optimized runner geometry and a robust divider/collector help reduce drive pressure and improve pulse energy to the turbine, supporting cleaner combustion under sustained load.

Why upgrade your ISX15 manifold

- Lower drive pressure & EGT: Flow-efficient runners reduce pumping losses during long pulls and heavy GCW routes.

- Turbo protection: Stable pulses and improved sealing help protect CHRA bearings and seals over long duty cycles.

- Thermal stability: High-nickel, thick-wall casting resists cracking and flange warpage from repeated heat cycles.

- Service friendly: Flat, machined faces and correct hardware locations support predictable gasket crush and quicker turnarounds.

Fitment

Applications include Cummins ISX15 and X15 engine families such as CM570, CM871, CM2250, CM2350 (and select X15 variants). Verify engine family/ECM label, emissions package (EGR/DPF/SCR), turbo flange style, and chassis clearances on the individual product pages before ordering.

Construction details that matter for fleets

- High-nickel thick-wall cast: Resists thermal fatigue and cracking in high-heat cycles.

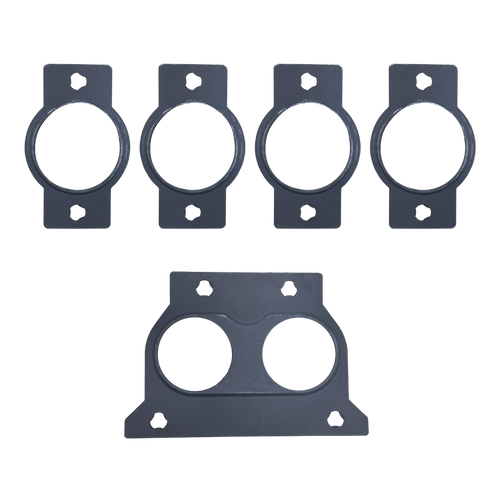

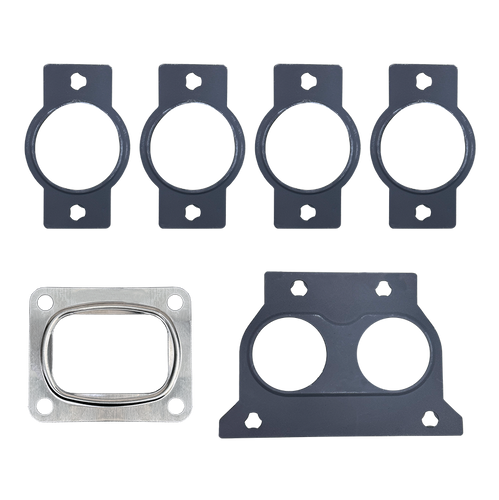

- Precision-machined flanges: Flat sealing surfaces at head and turbo reduce leaks and re-torque events.

- Reinforced divider & collector: Supports stable pulse energy and long-term structural integrity.

Choosing the right ISX manifold

- OE-style replacement: For fleets targeting reduced backpressure and improved sealing with stock-like packaging.

- Enhanced-flow configuration: For routes with sustained grade load and high ambient temperatures where extra thermal headroom is valuable.

Install & operations notes

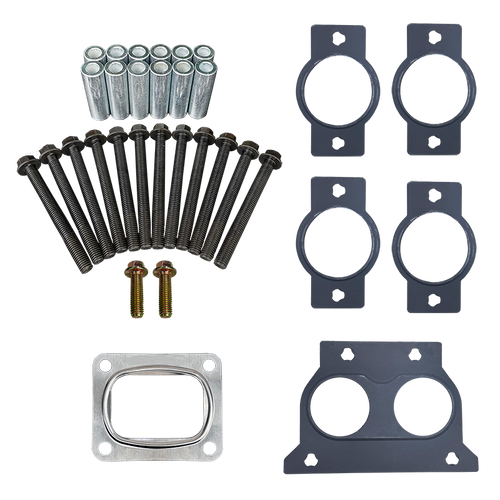

- Use new gaskets and recommended hardware; follow torque sequence on a cold engine and re-check if specified after heat cycles.

- Inspect turbo mounting face and clamp integrity; correct any upstream exhaust leaks that can skew sensor data and EGR strategy.

- Pressure-test CAC system and confirm MAP/DPF differential sensor health during post-install shakedown.

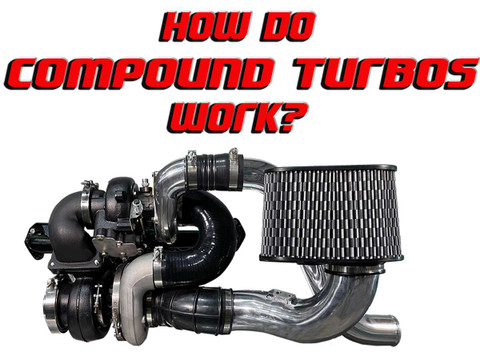

Building a full solution? See ISX15 Conversion Kits for turbo & plumbing conversion packages, or ISX Turbocharger Kits for single-turbo packages. Return to this page for manifold-only solutions.

ISX15 / X15 Cummins Exhaust Manifold FAQs

A high-flow ISX15/X15 exhaust manifold improves exhaust gas distribution to the turbocharger, reducing drive pressure and helping control EGTs during sustained load. Compared to factory manifolds, performance designs support steadier boost, better grade-pulling consistency, and improved long-term sealing reliability for heavy-duty and high-mileage applications.

Yes. Diesel Power Source ISX15 and X15 exhaust manifolds are engineered for specific engine families such as CM871, CM2250, and CM2350. When the correct manifold is matched to the engine family and installed properly, trucks can retain factory emissions equipment while benefiting from improved airflow and reduced exhaust restriction.

In most cases, a manifold upgrade alone does not require calibration changes. Many fleets and owner-operators see reduced drive pressure, cooler EGTs, and more consistent pulling power under load without altering the engine tune. If additional airflow or fueling modifications are present, calibration review may be appropriate to optimize boost and regeneration behavior.