Absolutely; 24V makes excellent daily driver when properly modified.

Why 24V excels as daily driver:

- Quieter operation: Significantly less noise than 12V at idle and cruise

- Smoother power: Electronic injection provides refined throttle response

- Better fuel economy: Computer-controlled injection optimizes efficiency (17-21 MPG highway stock)

- Cleaner exhaust: Less smoke than 12V at same power level

- Modern refinement: Factory gauges work, cruise control integrates well

Daily driving by modification level:

Mild (375-450 HP, S300 single, handheld tuner):

- ✓ Drives like stock with significantly more power

- ✓ Excellent fuel economy (15-19 MPG highway)

- ✓ Minimal smoke, civilized manners

- ✓ Perfect daily driver sweet spot

Moderate (450-550 HP, larger turbo, injectors, custom tune):

- ✓ Still very drivable with proper tuning

- ~ Fuel economy drops slightly (13-17 MPG)

- ~ Some smoke on hard acceleration

- ✓ Excellent for daily driving and towing

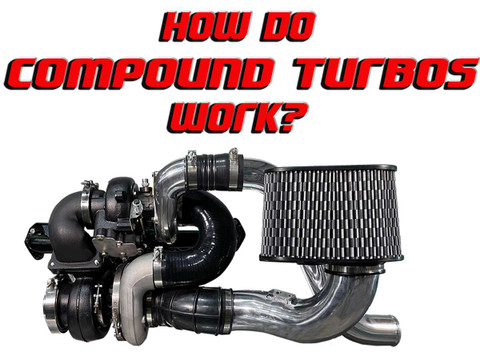

High performance (550-600 HP, compounds, full build):

- ✓ Daily drivable with compounds (no lag)

- ~ Fuel economy 11-15 MPG

- ~ Requires more attention to maintenance

- ✓ Incredible capability when needed

Real-world daily experience:

- Cold starts: Grid heaters work well, starts easily in cold weather

- Idle: Smooth and quiet (much better than 12V)

- City driving: Excellent throttle modulation, easy to drive conservatively

- Highway: Quiet, comfortable, good MPG if not using all the power

- Overall: More refined than 12V while making serious power