These Chevy-specific kits are modeled around 2500HD/3500 platforms to address frame rail spacing, steering shaft angles, HVAC clearances, and downpipe pathing. Whether you’re building a dependable tow rig or a strong daily driver, DPS components help your Cummins deliver torque with predictable temps and service access.

Why choose a Chummins conversion for your Chevy

- Cummins torque in a Chevy chassis: Pair commercial-grade power with the ride, interior, and stability you already like.

- Fitment that works: Cast and machined parts designed around Chevy bay constraints for repeatable installs.

- Thermal control: Manifold and turbine geometry aimed at lower drive pressure and steadier EGT on long grades.

- Serviceability: Sensor ports and hardware placement that keep maintenance straightforward.

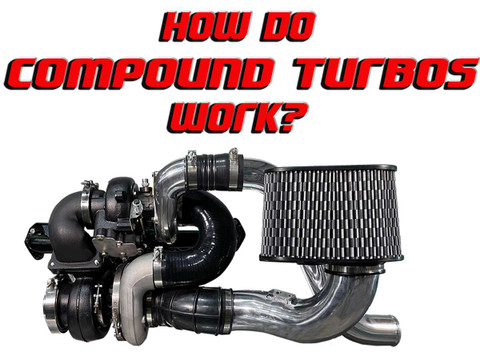

- Scalable options: From tow-focused singles to compound-ready paths as fueling increases.

Common Chevy applications

Support varies by model year and package. Typical targets include Silverado/Sierra 2500HD & 3500 across LB7, LLY, LBZ, LMM, LML, and L5P eras. Verify transmission choice, accessory layout, intercooler path, downpipe clearance, and oil routing on the product page for your year.

What’s in a typical Chummins kit

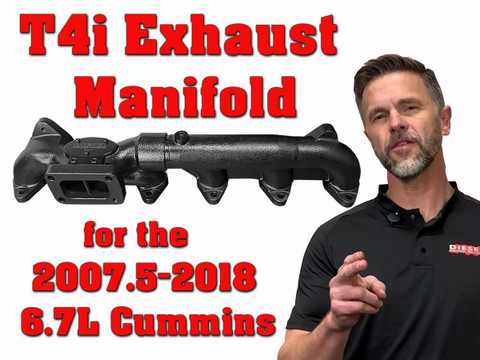

Application-specific turbocharger option, exhaust manifold or adapter as listed, hot-side and charge-air plumbing, oil feed/return solutions, clamps/couplers, brackets, heat shielding, and hardware. See each kit for exact contents and actuator/sensor provisions.

How to choose your Chevy setup

- Daily & towing: Early spool and steady EGT. Choose smaller to mid compressor sizes with matched turbine housing and a quality manifold.

- Street performance: Mid-size compressors with freer housings for stronger midrange while maintaining drivability.

- Higher-fuel builds: Larger airflow and freer A/R for headroom. Expect later spool; plan converter, gearing, cooling, and brakes.

Install notes for Chevy swaps

- Confirm transmission adapter needs, mount locations, and crossmember compatibility before ordering.

- Mock up hot-side and charge-air paths; check steering shaft, HVAC lines, battery tray, and firewall clearance.

- Use new gaskets and quality hardware; follow torque sequence on a cold engine. Pressure-test the charge-air system prior to first start.

- After shakedown, re-check fasteners, boots, and oil connections. Monitor boost and EGT on initial towing runs.

Building in stages? Explore S300 Single Turbos, S400 Single Turbos, and Diesel Exhaust Manifolds. For Ford-specific swaps, visit Fummins Conversion Kits.