6.7 Cummins Manifolds

6.7 Cummins Exhaust Manifolds | Performance 4th/5th Gen Upgrades

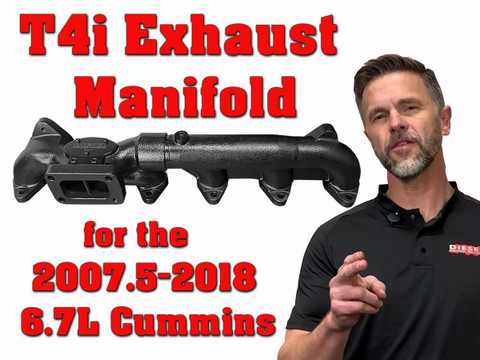

High-flow, crack-resistant manifolds engineered for heat control, faster spool, and long service life on Ram 2500/3500 6.7L Cummins.

Diesel Power Source 6.7 Cummins exhaust manifolds increase airflow, improve turbo response, and tolerate sustained heat better than thin factory castings. Whether you tow in the mountains, commute daily, or want dependable power for performance builds, these manifolds are built for durability and repeatable sealing. Choose a stock-replacement manifold for the factory turbo or a T4 performance manifold when upgrading to a larger turbocharger.

Why upgrade your 6.7 Cummins manifold

- Lower EGT under load: Smoother runners reduce drive pressure on long grades and heavy tows.

- Quicker turbo spool: Optimized collector geometry helps the turbo light sooner for stronger mid-range torque.

- Strength and durability: Thick-wall castings and reinforced partitions resist cracking and warping from thermal cycling.

- Stable boost control: Free-flowing passages support consistent VGT or wastegate control for towing and daily use.

- Service-friendly: Pre-tapped ports (where noted) simplify EGT/drive-pressure monitoring and diagnostics.

Fitment

Designed for Ram 2500/3500 with the 6.7L Cummins, model years 2007.5–2024. Review each product page for year-specific notes (EGR/VGT configurations), stud kit recommendations, and turbo flange style.

Which 6.7 Cummins manifold should I choose

- Stock-replacement (T3): Direct fit for the factory turbo. Ideal for emissions-equipped trucks, towing, and daily driving with cooler EGT and better drivability.

- T4 performance: For trucks upgrading to a T4-flanged turbo. Adds flow and a stronger foundation for higher power while maintaining street manners.

What you get

Application-specific manifold, hardware where noted, and pre-tapped sensor/pyro ports (see product listings for exact contents). All sealing faces are precision-machined for repeatable gasket crush.

Construction details that matter

- Thick-wall cast: Built for continuous load and repeated heat cycles common to towing and work use.

- Flat, machined flanges: Proper alignment at the head and turbo reduces leaks and re-torque events.

- Smooth internal runners: Minimizes turbulence and hot spots to support airflow and temperature control.

Recommended supporting parts

- New gaskets and quality hardware

- EGT and boost (or drive pressure) monitoring for heavy use

- High-temperature anti-seize on studs and fasteners

Built for towing, work, and performance

Owners report steadier speed on grades, fewer downshifts with a trailer, and cooler temps on long pulls. If you tow in high heat, at elevation, or on larger tires, a high-flow manifold helps the turbo stay in its efficiency range.

Planning a turbo change next? See 3rd Gen Swap Kits and Add-A-Turbo Kits.

6.7L Cummins Exhaust Manifold FAQs

A high-flow 6.7L Cummins exhaust manifold improves exhaust distribution to the turbo, reduces drive pressure, and helps control EGTs under load. Compared to the factory manifold, a performance manifold supports faster spool, steadier boost, and improved efficiency, especially during towing and long pulls.

A stock-replacement manifold is ideal for trucks keeping the factory turbo or VGT and wanting better reliability and lower backpressure with a direct bolt-on install. A T4 manifold is designed for trucks upgrading to larger frame turbos or planning future power increases. The right choice depends on turbo selection, towing needs, and long-term build goals.

Yes. When installed correctly, a performance manifold can reduce exhaust restriction and stabilize turbo operation, which helps lower EGTs and improve drivability even with factory emissions equipment in place. Many towing trucks see cooler temperatures and more consistent boost on long grades without requiring tuning for the manifold alone.