-

-

(1)

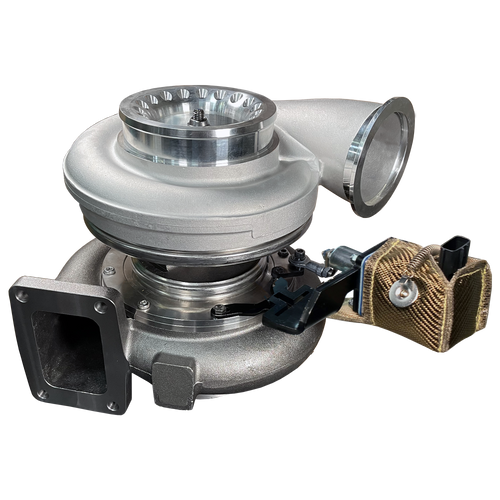

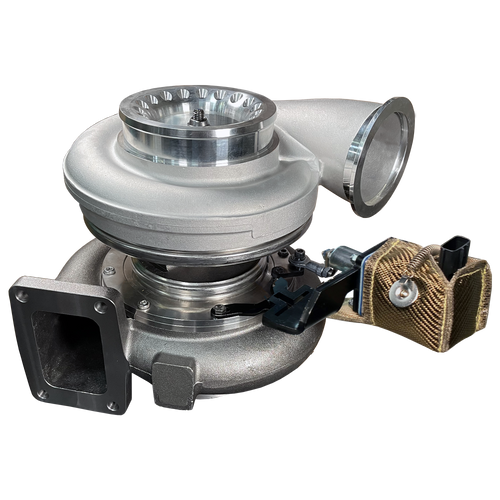

S400 Cummins ISX / ISX15 / X15 Complete Turbo Conversion Kit

Choose Options$4,799.00 - $4,999.00 -

-

-

-

-

-

-

-

-

-

Diesel Power Source ISX15 conversion packages are engineered for commercial duty where uptime, thermal control, and predictable boost matter. These kits improve airflow and reduce drive pressure/EGT while preserving OEM-like routing and service access on Cummins ISX15 and X15 platforms.

(1)

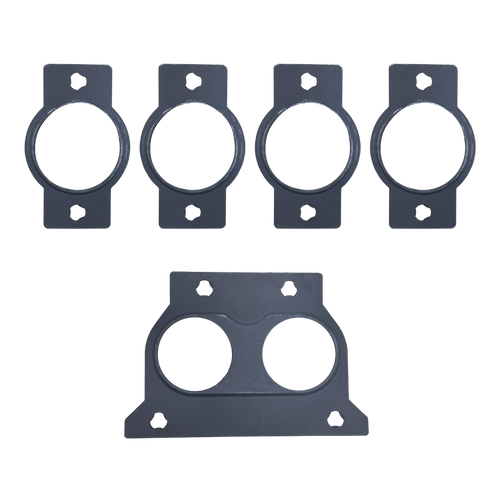

This category covers conversion systems—the brackets, manifold adapters, hot-side and charge-air plumbing, oil feed/return, and related hardware needed to change from a stock configuration to a specified turbo arrangement. If you only need a manifold or a single replacement turbo, see the dedicated categories linked below; use this page for a complete conversion path.

Intended for Cummins ISX15 and X15 families including CM570, CM871, CM2250, CM2350 (and select X15 variants). Verify ECM/engine family tag, emissions package (EGR/DPF/SCR), actuator style, chassis clearance, and charge-air routing on each product page before ordering.

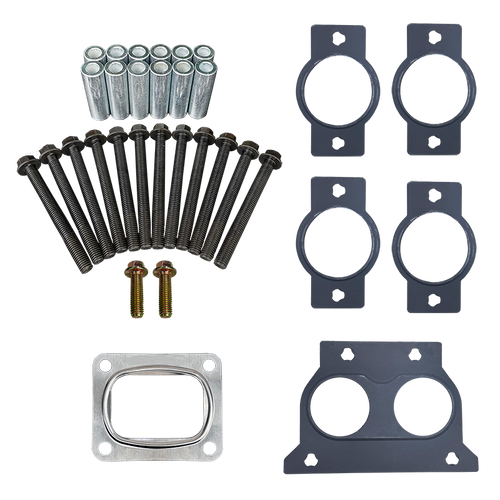

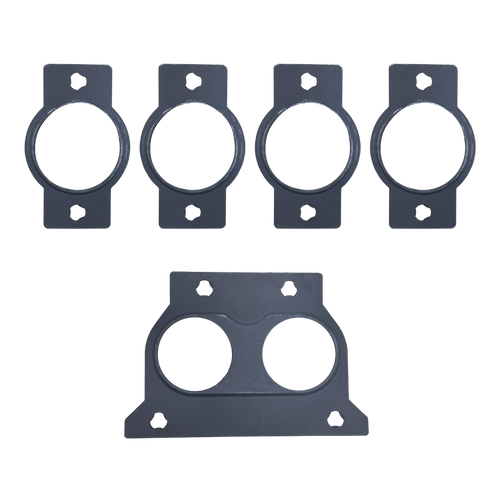

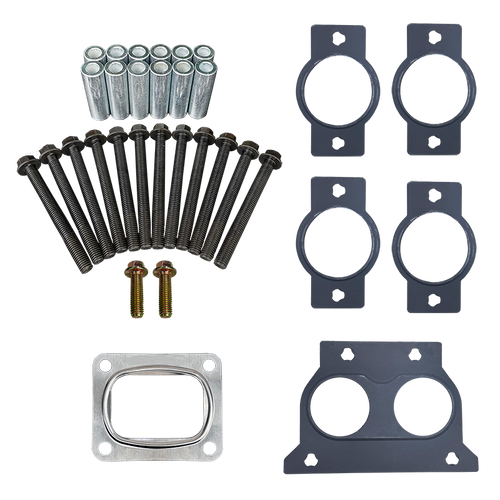

Application-specific turbo option(s), mounting brackets/adapters, manifold or manifold adapters as noted, hot-pipe and charge-air plumbing, oil feed/return solutions, clamps/couplers, heat shielding, and hardware. See each kit listing for the exact bill of materials, actuator provisions, and sensor port details.

Shopping related components? ISX15 Exhaust Manifolds (manifold-only solutions) | ISX Turbocharger Kits (single-turbo packages). Return here for full conversion systems that change your configuration.

A Cummins ISX15 or X15 conversion kit adapts a heavy-duty commercial Cummins engine for use in custom, vocational, or specialty truck applications. These kits are designed for builders who need extreme torque, continuous-duty reliability, and thermal control beyond what pickup-based diesels can handle. ISX15 conversions are commonly used for heavy towing, haulers, specialty rigs, and high-load applications where durability is critical.

Yes. Diesel Power Source ISX15 and X15 conversion kits are engineered around specific engine families such as CM871, CM2250, and CM2350. When the correct family is selected and the kit is installed properly, factory emissions equipment can be retained. Correct engine family matching is critical for actuator compatibility, sensor routing, and long-term reliability.

Not always, but many conversions benefit from calibration refinement after installation. Optimizing fueling limits, boost targets, and shift strategy can improve drivability, heat control, and load handling. Most builders monitor boost, EGT, and drive pressure on initial loaded runs to confirm the system is operating efficiently and without restrictions.