3rd Gen Swap Kits

3rd Gen Cummins Turbo Swap Kits

Upgrade Your 2nd Gen with Modern Turbo Technology

Want the performance and reliability of 3rd generation Cummins turbo technology on your 2nd gen truck?

Our 3rd gen swap kits provide everything you need to bolt modern turbos and manifolds onto 1994-2007 Cummins engines. Get better spool, more efficient airflow, and increased power potential while maintaining excellent fitment.

Upgrade to 3rd gen turbo and manifold design

Turbo, manifold, pedestal, all hardware included

Engineered specifically for 2nd gen chassis

Improved spool, lower EGTs, more power potential

Popular Applications: 1998.5-2002 24-valve VP44 trucks, 2003-2007 5.9L Common Rail trucks upgrading to larger turbos or compound setups.

3rd Gen Turbo Swap Kits - FAQs

A 3rd gen swap kit allows you to install modern 3rd generation Cummins turbo technology (2003-2007 design) onto your older 2nd generation truck (1994-2002), replacing the factory VGT setup.

Why upgrade to 3rd gen turbo design?

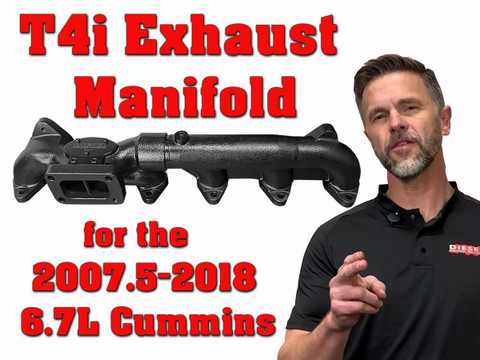

- Better manifold design: Improved flow characteristics and less prone to cracking than 2nd gen manifolds

- More turbo options: Access to wider variety of modern turbos and upgrade paths

- Compound turbo capability: Easier path to compound setups with 3rd gen manifold design

- Improved performance: Better spool characteristics and more efficient airflow

- Future-proofing: As 2nd gen parts become scarce, 3rd gen options remain abundant

This is especially popular for 1998.5-2002 24-valve trucks looking to modernize their turbo systems.

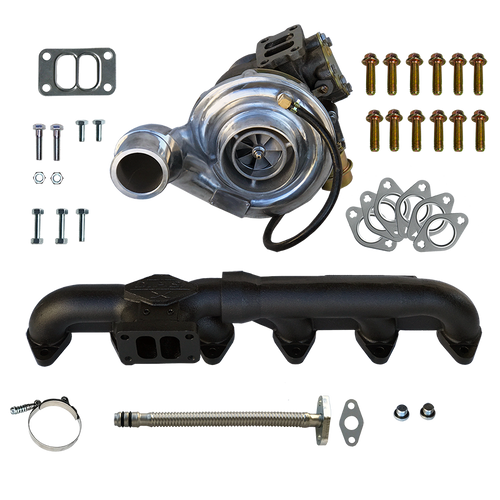

Our 3rd gen swap kits are truly complete—everything you need for the conversion:

- ✓ 3rd gen style turbocharger (size based on kit selected)

- ✓ 3rd gen exhaust manifold with proper mounting

- ✓ Turbo pedestal adapter (mounts turbo to manifold)

- ✓ All gaskets and O-rings

- ✓ Mounting hardware (bolts, studs, clamps)

- ✓ Oil feed and drain lines with proper fittings

- ✓ Downpipe or V-band adapter

- ✓ Installation instructions with photos

You will NOT need to:

- Hunt for adapter plates or custom fabricate mounts

- Source individual components from multiple suppliers

- Worry about compatibility between parts

Everything is engineered to work together and bolt into your 2nd gen chassis.

Our 3rd gen swap kits are designed for:

- 1998.5-2002 5.9L 24-valve (VP44): Most popular application. Direct bolt-in with kit components.

- 2003-2007 5.9L Common Rail: Factory uses 3rd gen manifold, but our kits allow turbo upgrades with proper mounting.

- 1994-1998 5.9L 12-valve: Possible but requires additional modifications (different oil drain, possibly exhaust work). Contact us for specifics.

Important considerations:

- Automatic vs. manual transmission affects downpipe routing

- Exhaust brake presence affects turbo selection

- Aftermarket headers or exhaust may require additional adapters

Each product page lists specific fitment details. Not sure? Send us your truck specs (year, engine, trans, current mods) and we'll confirm compatibility.

Power gains depend on which turbo size you choose and your supporting modifications:

- S300-based kits (S362, S366): 400-550 HP with proper tuning and fueling

- S400-based kits (S472, S475): 600-800+ HP (requires big injectors, dual CP3s, built trans)

- VGT-based kits: 350-450 HP with excellent street manners

Beyond just peak horsepower, you'll notice:

- Faster turbo spool and better throttle response

- 150-250°F lower EGTs when towing

- Smoother power delivery

- Better low-end torque (especially with properly sized turbo)

- Reduced smoke at part throttle

The real benefit isn't just peak power—it's having a modern, efficient turbo system that makes your 2nd gen feel like a completely different truck.

Moderate to advanced skill level required. This is more involved than a direct replacement turbo.

Installation time:

- Experienced DIY: 8-12 hours

- First-time installer: 12-16 hours (plan for a full weekend)

- Professional shop: 6-8 hours ($900-1,400 typical labor)

Why it takes longer than standard turbo swap:

- Removing old 2nd gen manifold and turbo completely

- Installing new 3rd gen manifold with different bolt pattern

- Routing oil lines differently (3rd gen has different connections)

- Adapting downpipe to new turbo outlet

- Ensuring proper clearance with engine bay components

Tools needed: Full socket/wrench set, jack and stands, penetrating oil, torque wrench, possibly cutting/grinding tools for downpipe work.

Our kits include detailed photo instructions. We also offer phone/email tech support during your install.

Yes, tuning is essential for optimal performance and safety.

Your stock ECU programming doesn't account for the increased airflow capability of the new turbo. Without proper tuning:

- You won't see the full power potential

- Truck may smoke excessively

- Drivability can be poor (surge, lag, rough power delivery)

- EGTs may not be properly managed

Tuning options for 2nd gen trucks:

- VP44 trucks (98.5-02): Smarty, Quadzilla, TST PowerMax, or custom tuning via SCT/Diablosport

- Common Rail (03-07): EFILive, H&S Mini Maxx, SCT, or Smarty

We recommend working with a tuner experienced with 3rd gen swap setups. They'll optimize boost levels, fueling, and timing for your specific turbo configuration.