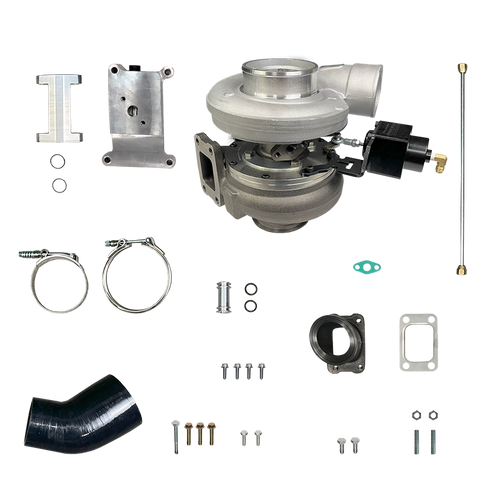

Installation is straightforward—similar to replacing any stock VGT turbo.

Installation time:

- DIY with mechanical experience: 4-6 hours

- Professional installation: 3-4 hours ($500-800 labor)

Why installation is easier than fixed-geometry turbos:

- Direct bolt-in: Mounts exactly where stock turbo was located

- Same oil connections: Uses factory oil feed and drain locations (no custom lines needed)

- Factory downpipe compatible: Often works with stock or aftermarket downpipes without modification

- Electrical plug-and-play: VGT actuator connector plugs into factory harness

- No custom fabrication: Everything fits using factory mounting points

Installation steps (overview):

- Disconnect batteries and remove intake system

- Disconnect VGT actuator electrical connector

- Remove oil feed and drain lines

- Unbolt downpipe from turbo

- Remove turbo mounting bolts and remove old turbo

- Install new Turbonator VGT (reverse removal process)

- Perform VGT actuator relearn procedure (via scan tool or tuner)

Tools needed: Socket set, wrenches, jack and stands, penetrating oil, torque wrench. No special tools required.

Our kits include detailed photo instructions and we offer phone/email support during installation.